GeoLink - more than ‘just’ a sprayer guidance system

Toro GeoLink is a guidance and sprayer boom control system and management package rolled into one. Here James de Havilland, independent machinery tester, finds out how this technology will vastly improve sprayer application accuracy.

James de Havilland

Technical Freelance WriterFirst impressions

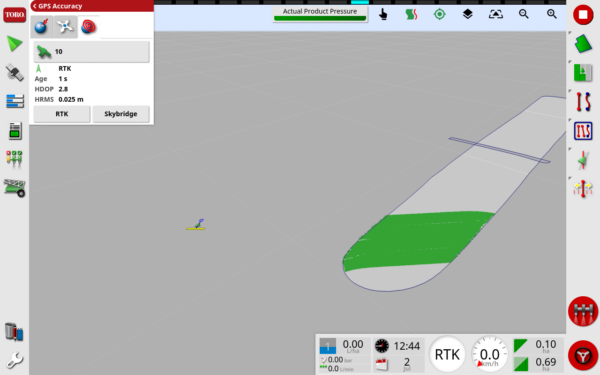

Everything about the demo Toro MultiPro 5800-G sprayer looked familiar. With its low profile 1,136 litre tank, high capacity six-diaphragm pump and 50hp Kubota petrol engine, this quiet sprayer looks perfectly matched to its 6.25m wide, 12-nozzle boom. Where this demo model differed, however, was that it was fitted with Toro’s GeoLink guidance and course mapping and Autosteer system, a large detachable 12inch XD+ touchscreen clearly showing the area to be sprayed as it was used to ‘map’ the area. This screen is the interface to the GeoLink system that makes this Toro MultiPro more than just a dedicated sprayer, but rather than adding complexity it was all set to make working the MultiPro a lot simpler.

Rather than try to understand how GeoLink works, I thought it best to concentrate on what it can do. The system was initially set up to map a golf course, showing fairways, tees, greens and other areas that may need spraying on the screen as appropriate. Using outlines of the areas that need to be sprayed, the exact area to be sprayed and subsequently treated is accurately recorded. The test fairway was originally said to cover 1.79acres (0.725ha). When mapped using GeoLink, done by simply driving around the outer edge of the fairway to record its outer perimeter, the true area was shown to be 1.85acres (0.750ha).

Accurate area measurement is hugely relevant. When ordering materials to be applied to a given area, the precise amount needed can be established with the help of GeoLink generated maps. This can lead to not just savings on material costs but also ensure the benefits of the applied materials are optimised.

What is perhaps of equal importance is routine working with a GeoLink equipped sprayer. On a typical day, the sprayer operator can start a job only to find conditions change, such as the wind picking up or it starting to rain. With GeoLink, the on-board screen makes it easy to stop work and then resume spraying exactly where they left off when conditions improve. There is a much-reduced risk of missing out part of the job or over spraying a treated area. Actual spray application coverage is recorded, with any missed areas shown on the screen or when accessed later.

Every job is recorded and the spray data retained for later use, with it being simple to note spray conditions prevailing on the day. This enables the operator to compare conditions when the material’s applied and see if this had an impact on the results. Was it too hot or cold for the material to work effectively? Was the application rate too low or high? Was the job carried out following rain or did it rain soon after? Further, the recorded data may be uploaded into some course management software.

As to using the GeoLink guidance, there is no question that spraying with a GeoLink equipped sprayer will be faster and more efficient than using alterative blobber marker or dye based guidance. Doing away with the disadvantages associated with these marking systems is a clear plus but with autosteer the MultiPro 5800 was so easy to use I could confidently say with just a little practice I could tackle a spraying task safe in the knowledge the job was done without misses or over spraying between bouts. If I did mess things up, the mapped spraying area would enable any application errors to be more easily rectified.

As anyone who has worked with an autosteer system will recall the initial feeling of letting a machine steer itself initially appears unnerving but once I appreciated the system is working, the self-steering element soon felt ‘normal’. On the Toro MultiPro, the steering wheel stays in work, even when the sprayer follows a curved line. It was easy to just let the system do its stuff.

All it took to take over from the auto-guidance at the end of a spray pass was to take over the steering wheel and turn around the sprayer back to where I wanted to resume work. GeoLink took care of shutting off individual nozzles both during the turn and when a few bout matching misalignments would have led to overspraying. Where I had missed areas by poor bout matching, this showed up too. The trick is to turn outside the spray area, broadly align to the next bout and then let auto-steer take over.

We worked over a fairway that included a deep gulley running across its upper width. For a simple test, we decided to just stop spraying. Without interrupting the self-steering, the sprayer turned off manually and the skipped area recorded on the display. When we resumed spraying, it was just a case of touching the screen to set it going again. This action can be recorded so it will happen automatically the next time the job is carried out.

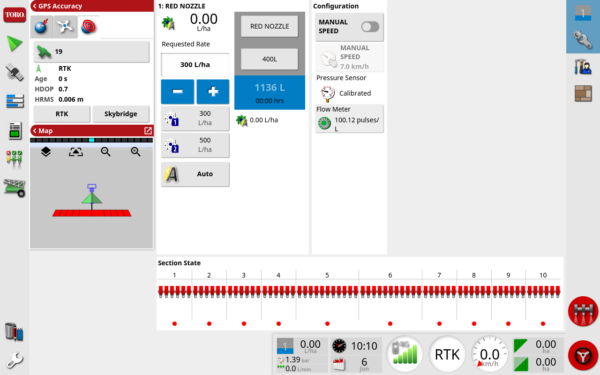

Better still, the system can be used to ‘draw’ an exclusion area onto the spraying map then and there. The newly added ‘no spray’ area can be retained or removed just as easily. We had added an area to mark a drive crossing the fairway, crossing this at varied angles to see how effectively the boom nozzles shut off and restarted. There was no spray on the hard surface, despite repeated crossing at varied approach angles. It was the ability of the system to look after each individual nozzle that was impressive. A point to note is the four nozzles in the boom centre section are controlled in pairs.

Look, no hands! For some, the ability to specify a Toro MultiPro 5800 with GeoLink for ‘self-steer’ spraying will be of key interest, but auto-guidance potential is just a part of what the system has to offer. Aside from enhancing sprayer accuracy, GeoLink can form an integral part of overall course management.

In work, the GeoLink system will control the nozzles automatically, cutting each one off in turn to match overlapping bouts or, as pictured, when overlapping an area that is not to be sprayed, such as the perimeter of the fairway, rough or bunker. If the spray job is interrupted, the operator can return to work, the system recalling where it has worked and only spraying the remaining areas that need to be treated.

The demo MultiPro 5800 had ultrasonic boom levelling fitted. This option automatically raises the outer boom tips to cope with not just the obvious lumps and bumps in the fairway but the less clear sections too. My stint on the sprayer saw the booms note some of the undulations I hadn’t noticed and in accordance the boom sections rased to include the lip between the drive we had marked on the map. This did away with the risk of the tip of the boom getting too close to the ground, something it is all too easy to miss when spraying over undulating ground.

It is clear GeoLink can reduce the pressure on the operator but added ultrasonic boom levelling was the icing on the cake. I felt even I would be able to tackle spraying using this GeoLink MultiPro. It is clear this tech will have ‘labour utilisation’ implications. Currently, spraying is a job tasked to the most experienced staff. Could GeoLink change that?

GeoLink, even without autosteer, has a great deal to offer as it automates the control of the spray boom, switching nozzles on and off to prevent over spraying when matching bouts. Following the on-screen spray map makes it easy to see where there are missed areas that need to be sprayed, with accurate data showing the area covered and amount of material applied.

GeoLink is a guidance and sprayer boom control system and management package rolled into one. To suggest it will make course spraying simple could be misleading, but the skills needed to do a good job are much reduced.

The operator can take over steering and stop spraying quickly and easily, enabling areas to be excluded or, as pictured, stop spraying to accommodate a deep gulley. GeoLink flexibility enables existing maps to be easily modified and exclusion areas to be added ‘on the fly’. Trees and obstacles can be also included into the map.

A driveway or path across a fairway can be added as an exclusion area, GeoLink automatically switches off the nozzles as appropriate as the drive is crossed. Even when the operator varies the approach angle to the drive, the system will react accordingly.

Keeping it brief:

- Toro GeoLink is a specialist turf precision spray system that offers precision guidance or autosteer with individual nozzle control. By teaming up with established guidance specialists Topcon, Toro has been able to develop its own in-house system dedicated to the needs of turf professionals using proven hardware. Toro GeoLink is not based upon software developed for agricultural applications.

- GeoLink will vastly improve sprayer application accuracy and remove the need for blobber or dye marker systems.

- Increased potential for chemical cost saving and optimised performance thanks to individual nozzle control and accuracy. Potential bout to bout pass accuracy of between 1-2cm.

- GeoLink will ease the recording of application rates, with coverage maps to show areas sprayed, material applied, application rates and, if desired, recorded wind speeds and temperatures.

- If a spray task is interrupted, it’s easy to resume the task from where it was stopped.

- Easily varied route tracking to reduce compaction with ‘no spray’ areas being added or removed ‘on the fly’.

- Obstacles to be avoided can be entered onto the maps.

- An operator with a sprayer certificate will be able to work a GeoLink equipped sprayer without specialist additional training.

- Autosteer enhances the system’s ease of use and efficiency, but the system can be worked by steering the sprayer, using on screen guidance to match bouts. GeoLink can be retrofitted to some Toro MultiPro models made from 2019, with autosteer only offered on MP5800 units made for the 2022 model year.

-

Within the Autosteer system there is the ability to map guide-lines for the machine to follow when spraying. To avoid wheel marks from constant travel, these guides can be nudged over to suit the course needs.

-

GeoLink is extremely flexible, allowing operators to switch to a completely different spraying pattern as seen on the screenshot to the left.

-

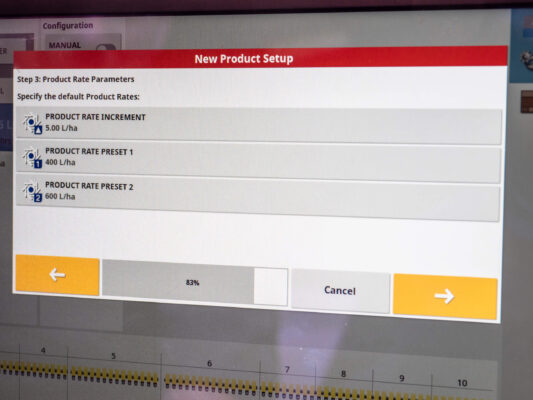

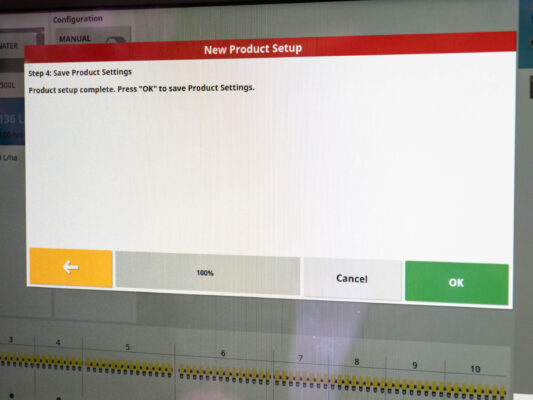

To suggest anyone can just jump on a GeoLink enabled MultiPro and just go spraying would be misleading, but set-up is not complex. Once a course has been mapped, key spray mixes and application rates entered and operating parameters set, an operator can spray safe in the knowledge that the task will be completed to spec, using the correct application rates with excellent pass to pass accuracy. The spray job is stored both within the main memory of the control screen as well as on a USB stick to allow easy transfer to a management software system. At present automated WiFi job recording is not available.

-

Setting up spray product details is eased by the GeoLink menu system working through the various steps.

-

Of equal importance, the ‘recipe’ can be tweaked to suit prevailing conditions without upsetting the core setting, such as altering the application rates.

-

After a short while, several key tasks will be installed within the GeoLink memory, the operator selecting the job to be carried out and then checking against the parameters laid down for a given area to be sprayed. For technical support, Reesink can remotely access the machine to assist if any troubleshooting is needed.

-

Aside from the control screen, the key hardware elements of the GeoLink system include a GLOBAL control modem (right).

-

This will link to the strongest mobile telephone network as appropriate, satellite and RTK receiver on the roll frame with a machine-to-machine antenna option to the right.

-

Finally there are the nozzle control solenoids – that latter control individual nozzles on the boom sections, the central pair controlling two central nozzles each.

Simple questions

Will the signal to the GeoLink system suffer if a course is lined with tall trees or in a valley?

Short answer is yes, but not necessarily to the point where it will not work. GeoLink will ‘patch’ into the companion SkyBridge satellite system to enable it to continue to ‘see’ where it is to maintain accuracy in a RTK signal blackspot. This oversimplifies what is a complex back-up system, but GeoLink may work on courses where it may not be considered viable.

Can a course install an RTK base station to ensure a good connection for GeoLink?

It is possible if the budget allows. In most parts of England, existing RTK coverage is good, with Reesink using a couple of apps to establish basic RTK access before suggesting to a customer a signal may be available. If RTK is not available it may be possible to work with others to have a base station installed as the costs will typically need to be shared for it to be viable. Reesink will only offer GeoLink to customers where it can be guaranteed to work.

Once GeoLink is up and running are there ongoing costs?

Yes, users will need to pay a subscription to access the RTK signals and SkyBridge. Subscription packages lasting from one to five years are available.

Is there a GeoLink mower guidance system?

Not yet…

Reesink has developed its ROVER pre-sale mapping system that enables a course to be checked for access to a solid RTK signal and mapped ahead of GeoLink system installation. In outline, the system uses the core GeoLink hardware, the portable kit fitting to a buggy with a 12v supply.

If a course is not suitable for use with GeoLink, or it has signal ‘blackspots’ that cannot be covered by the complimentary Sky Bridge system, this will be determined ahead of time.