Toro eTriFlex 3370

James de Havilland is a Technical Freelance Writer hailing from Banbury in Oxfordshire. A well-respected journalist, he has accrued over 30 years’ experience operating, testing and writing about turfcare machinery.

First impressions

Climb onto a Greensmaster eTriFlex 3370 for the first time and there is every chance you will feel perfectly at home. The steering adjusts to suit in familiar Toro fashion and the travel pedal is positioned exactly where you’d expect it to be.

The dash has an ‘ignition’ key, raise lower lever and a switch to select neutral, as well as a choice of two travel speeds. There are various operating parameters that will be set up via the InfoCenter, but for basic operation, that’s about it. Release the brakes, select drive, press the travel pedal and away you go.

It’s when you turn the machine on that you get the first noticeable difference – it’s so quiet you will wonder if it is actually on! But from thereon in it’s all about the cut and the finish. Rest assured being all-electric certainly hasn’t taken away from the quality of cut you’d expect from a Toro greensmower…

It’s all about the finish

Initially, ignore the fact that the silent running eTriFlex 3370 draws its energy from a 10.77kWh lithium-ion battery pack. Gloss over the elimination of an engine and hydraulics. Concentrate first on quality of cut and finish.

With its intelligent electronic control of the traction motors and precise monitoring of the cylinder speeds, the eTriFlex exactly matches these to the radius of the turn, ensuring a clean radius cut and scuff free turns.

Both the eTriFlex 3370, and its hybrid sibling the eTriFlex 3360, are fitted with the Toro Radius Dependent Speed system (RDS). When carrying out the clean-up cut around the perimeter of a green, the RDS actively controls the speed of the inner, central, and outer cutting units to match the rotation speed of the driven wheels.

In simple outline, RDS compensates by adjusting each of the three cylinder’s speeds independently to ensure a consistent clip rate across the width of the mower by matching how far each one must travel to match the radius of the curve. The RDS electronics also govern the traction motor speeds, adjusting the rotation of the wheels to ensure a perfect match to the curve to eliminate tyre scuff.

This all sounds impressive on paper but in practice the only way to put RDS to the test is to ‘feel’ it in action; you cannot see the system working. Turn the steering wheel, and you can sense the wheels actively driving through the curve of a clean-up cut. The effect is even more noticeable when turning between bouts.

The demo eTriFlex 3370 had the optional rear wheel motor fitted, and it was possible to pick-up the gentle added drive from the rear wheel as the turn was made. You can sense the mower powering itself through the turn, but not in an aggressive way.

Fully electric, the steering only comes alive when the mower is on. Grab the wheel to climb aboard, and the wheel turns with no resistance.

When mowing, there is no steering feedback with no weighing up as you dial in more lock. It is easy at this point to suggest this is not exactly what you want from a precision bit of mowing equipment, but it is perhaps more accurate to suggest the steering is something you just stop noticing. Within a few minutes, driving the eTriFlex 3370 feels familiar. Hard to explain, but it is when you go back to piloting something with ‘conventional’ hydraulic power steering that you notice the difference.

Another thing you notice when climbing back onto a mower with an engine is that the latter, no matter how quiet, delivers a subtle exhaust note as an ever-present companion. You also ‘smell’ the difference, the eTriFlex 3370 delivering just the aroma of cut grass. Stealth mowing with an eTriFlex is perfectly possible – and inherently enjoyable.

The eight individual battery packs are positioned under the ‘bonnet’ (as seen above) and in two side pods. Delivering 10.77kWh at 48v, the Samsung SDI batteries should deliver enough power to easily mow 18 greens, with Toro suggesting 22 as an average with the caveat that a great deal will depend upon the course, terrain and ambient temperatures.

An overnight charge will restore the batteries to full capacity, the blue cable main power connector first needing to be detached to allow the charger to be hooked up.

The charger itself draws power from a conventional 13amp plug and is small and light enough to be easily portable.

A third traction motor is an option and is one you will notice doing its job in a tight turn. The Toro RDS system accurately monitors not just the speed of the cutting units but the speed of the wheel motors too, motors with active drive to the outer wheel in a turn helping to eliminate tyre scrub. In a turn, you can ‘feel’ the motors helping to pull the mower through a curve.

The traction motors have regenerative braking, the mower slowing as you ease off the drive pedal. Power modulation is extremely smooth, making the eTriFlex 3370 simple to control.

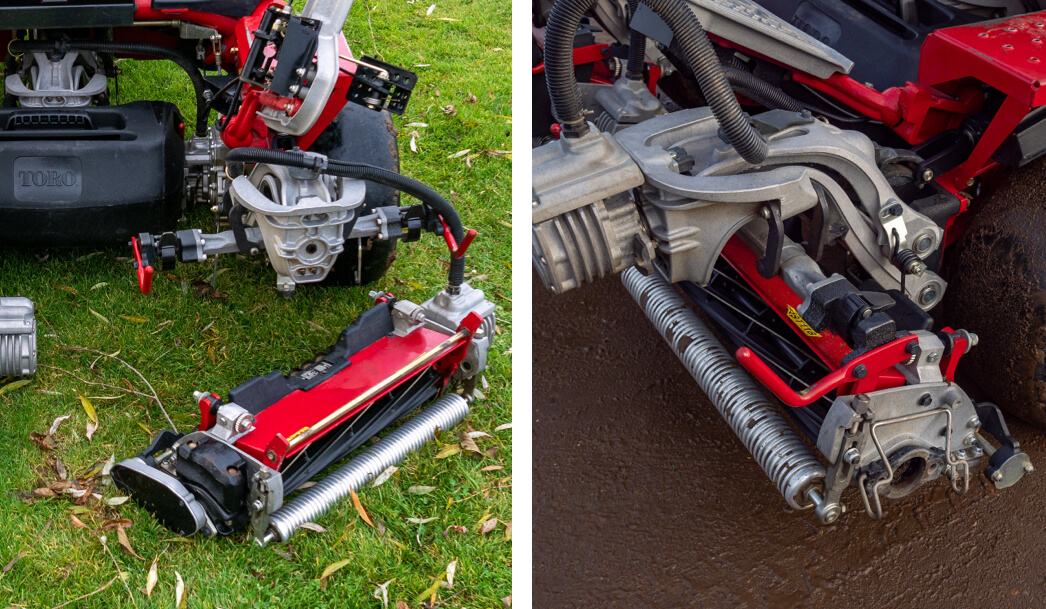

Snap-on quick-connect cutting units are now an established Toro feature, with a mount on the double A-Arm suspension retaining a detached cylinder motor (above right) when the cylinder is removed for servicing. This can be done without tools.

Just about the only items on the eTriFlex that make any noise are the lift actuators, but that’s just a gentle whirr accompanying a speedy lift and lower.

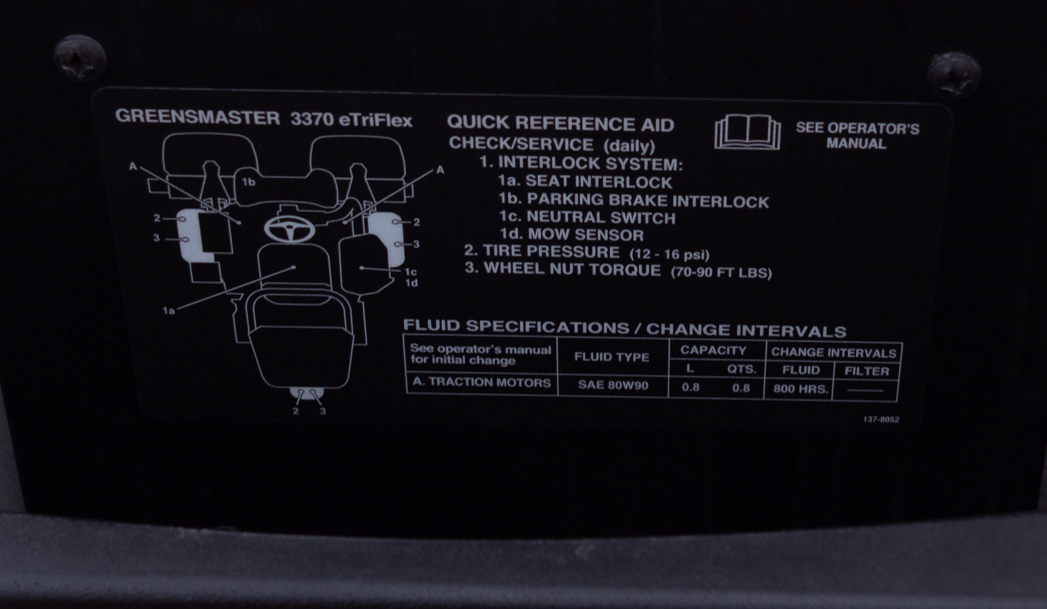

The quick reference aid decal on the back of the seat says a great deal about the simplicity of both operating and caring for an eTriFlex 3370. You do not need a grease gun, daily checks are minimal and you can forget your ear defenders too.

Looking pretty much the same as the InfoCenter on existing Toro mowers, the unit on the eTriFlex 3370 has a few extra features, to include a battery reserve. This can be set so there is a fixed reserve of battery power to drive back to base should the mower run out of mowing power. The mower automatically applies a parking brake when the operator leaves the seat.

Familiar triplex looks betrayed only by a lack of grills in the engine hood. Operating an eTriFlex 3370 requires no extra training, a simple outline of the basics easily covers all an experienced operator will need to know.

The Lift-Gate footrest system is carried over from eTriFlex models and provides really good access to the Quick-Change central cutting unit. The advanced Double A-Arm suspension and Lift-In-Turn system delivers both vertical and lateral unit movement for a consistent finish in a turn. This is something you will notice on the clean-up cut around an undulating green.