Reducing the total cost of ownership in turfcare

Have you ever heard the saying “buying cheaper means paying more?” Applicable to most purchases, but especially true for turf maintenance equipment, it means that if you buy something cheap, it’s more likely to be poor quality and break, wear out or not be fit for purpose. As a result, you’ll need to buy a replacement, costing you more money in the long run.

The fact is, behind temptingly low upfront costs lies a range of hidden expenses that will accumulate over time and bring the real cost up. When shopping for new rotary or cylinder mowers, aerators, irrigation systems or other essential turfcare equipment, having a clear vision of upfront costs and projected, long-term expenses – or Total Cost of Ownership – can help you get the best value for your budget.

Purchase price

First up, the purchase price. It’s often the main factor considered before investing in new machinery and the purchase price for one brand can be more than the next, but why is that?

It’s important to consider the quality, productivity, and durability of the brand you’re considering. These three things combine to ensure that all important value for money.

Quality

The quality of something can be determined by comparing a set of characteristics with a set of requirements and, specifically in manufacturing, adhering to set specifications, standards, and practises throughout the production process to consistently deliver products that meet or exceed customer expectations and maximise customer satisfaction.

Productivity

The productivity of your machinery is measured at the rate at which the work is performed. Key variables include cutting width of the mower and operating speed. Also worthy of consideration is what features does the machine have that benefits productivity? For example, will you need to roll the area after it’s been mowed or is there a roller on a mower? Would you need to blow the cut grass away or does the mower have a collector?

The more productive the equipment, the more jobs you can get done, and the more profitable the machine will prove to be to you.

Investing in the most up-to-date technological machinery usually delivers higher productivity levels. However, older machines can still deliver high productivity levels and be the right choice for your work. That’s why we sell on preloved Toro mowers through our Ree.Own scheme, which offers higher quality machines at a reduced price. With used Toro machinery, you can get quality, robust machinery without having to compromise and opt for a lower-quality brand.

Durability

A durable machine has the ability to last over time, resisting wear, breakage, and deterioration. A mower that can withstand the rigors of regular use and the elements will save you money in the long run. Important factors to consider: are the materials used high-quality materials in their construction? Has the finished mower been through rigorous testing standards to ensure they can handle the toughest mowing conditions? Has it been proven that these mowers and their parts can give hundreds of hours of work on the regular? All important questions that Reesink’s experienced, knowledgeable team of representatives and its dealers can help you with.

Now we’ve considered everything that’s pertinent to the purchase price, what comes next?

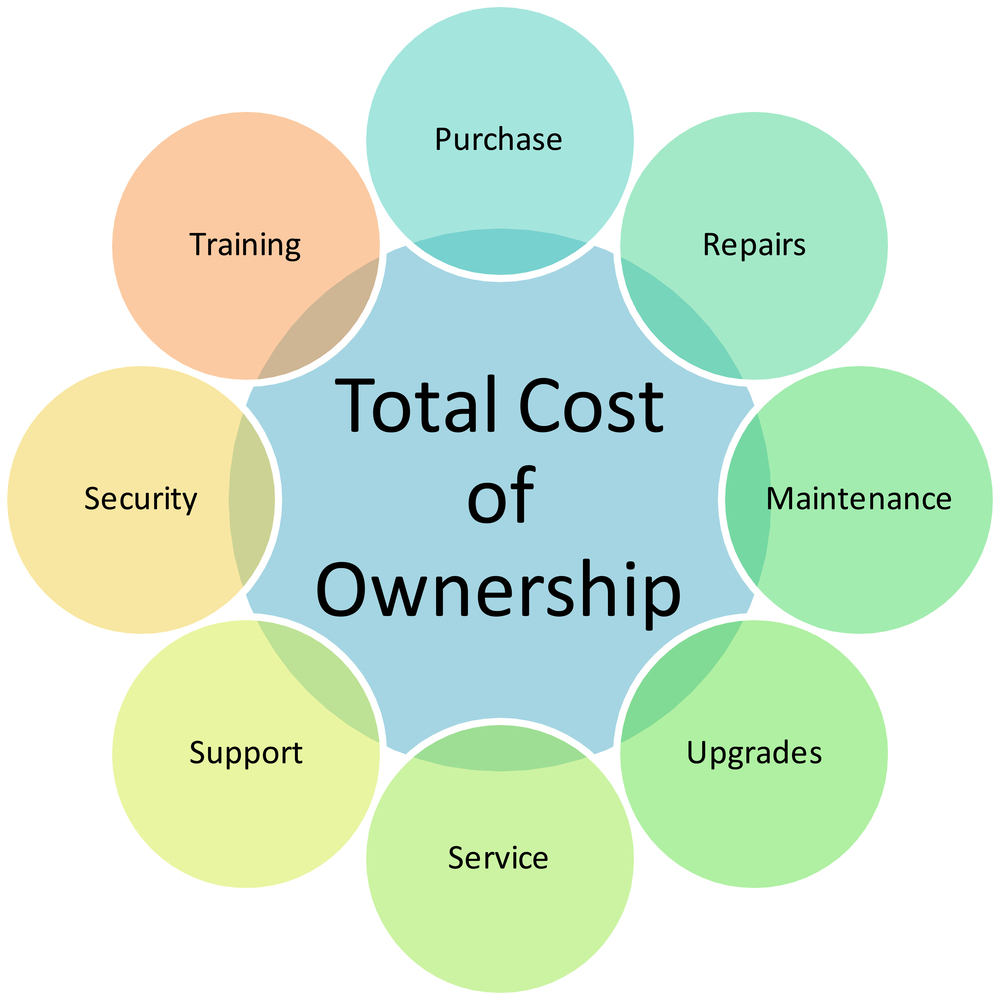

Total cost of ownership

As a simple formula, total cost of ownership is the purchase price of a product plus any additional costs associated with that product throughout its life cycle.

Focusing on TCO gives you a data-driven approach that is critical to make optimal decisions with your budget allocation. It will also help you understand why seemingly ‘cheap’ machines often hide unexpected costs and why ‘expensive’ ones can offer more value in the long run.

Why is TCO hard to calculate?

It isn’t always clear what counts as post-purchase cost, and some key variables can be elusive. In the context of turfcare machinery, we can explore operating costs such as maintenance, fuel, and labour relatively easily, but other factors such as potential downtime and the rate of depreciation are harder to predict and quantify.

To mitigate this challenge, it’s important to define the scope of these secondary costs from the start to minimise ambiguity and create a transparent framework to track all expenses.

Operating costs in turf management

Assuming your acquisition costs will be fairly straightforward when calculating your TCO, it’s worth spending some time clarifying what other expenses you might encounter.

Once everything is clear, you’ll be able to estimate your TCO in detail, and the resulting data will inform your decisions in procurement, maintenance, labour, and energy management – improving savings and ROI. Here are a few parameters to consider…

Maintenance

Build quality, durability and quality assurance are all factors influencing a machine’s life span: the better they are, the longer they last, and less maintenance is required.

That said, a healthy maintenance regime, with periodic routine checks and upgrades, should always be implemented. For instance, regularly greasing your machines, changing air filters or oil are small steps that will likely prevent big issues and expenses in the future.

When maintenance checks are carried out by trained machinery operators, they will recognise early symptoms like noise or vibration changes that might evolve into complex problems if left unaddressed.

As the total cost of maintenance encompasses unplanned repairs plus routine servicing costs, investing in quality machines and meeting all maintenance requirements will lower unforeseen expenses in the future.

Fuel

Fuel costs can take up a large portion of your budget, but there are many variables involved here.

In general, more demanding mowing conditions – cutting height, thick grass or steep hills – will require more power and hence consume more fuel. Different types of mowers will also have an impact. A cylinder mower for example can require 50 percent less horsepower per inch of cut than a rotary mower, and liquid cooled engines will consume less than their air-cooled counterparts.

Even the condition of your machinery plays a key role here: having blunt blades, poorly adjusted attachments or defective cooling systems are all factors that will worsen your mowing conditions and increase fuel consumption.

Labour

When considering full-time employees, labour is a more predictable cost, mostly comprising of salaries and benefits. The value your staff delivers, however, can vary significantly and depends mostly on you: empower them with the right tools and training, and they will achieve remarkable results.

This is why it’s essential you prioritise mowers designed to be comfortable and easy to use the whole day, allowing for long and productive hours of work that won’t affect the well-being of your employees.

Downtime

Safe and comfortable equipment helps you prevent people ‘downtime’, but what about your machines?

The true cost of downtime can be elusive because it includes fixed expenses – for instance, employees who won’t be able to work due to equipment being out-of-action; and unexpected expenses – for instance, a part breaks or the engine incurs a problem.

While unexpected challenges are always lurking, investing in quality equipment, and following a regular maintenance programme with the support of ReeAssure maintenance plans for machinery servicing and upkeep will minimise the chance of downtime.

Depreciation

Although not strictly a cost, depreciation can heavily affect the lifetime value of your machines. Many clubs rely on selling on or exchanging older machines for new ones. But if you invested in cheap machines that depreciate quickly or without a reputation for being reliable, you won’t be able to recover much from the initial acquisition price. In some case, you might even struggle to find a buyer.

How to choose turf machinery with TCO in mind

The key is shifting from a mindset that prioritises lower costs to one more focused on increasing the total value of your investment.

Thus, following the parameters highlighted above, you should look for a manufacturer that:

- Reduces maintenance costs with quality and durable machines

- Promotes fuel savings with innovative and efficient technology

- Supports the health of your team while enhancing performance

- Minimises downtime with reliable parts and models

- Depreciates slowly and is always on-demand – its reputation is an additional asset

Any brand name that comes to mind?

The Toro advantage

Toro has been a leader in the turfcare sector for over 100 years. Its name is synonymous with excellence and innovation and offering significant competitive advantage when it comes to total cost of ownership.

Indeed, Toro machines are known to be extremely reliable, comfortable, and easy-to-use, tough and durable while also delivering impressive performance even after many years of sustained use.

Toro’s bustling R&D department means you will have access to cutting-edge solutions designed for the needs of an evolving market and the support of a strong and committed distributor network. It’s an advantage that may not always be top of mind during the acquisition process but selecting a brand with a strong local channel partner provides a significant benefit to enhance the overall value and ownership experience during the life of your Toro products.

Wish to learn more about Toro’s offering? Call 01480 226800, email info@reesinkturfcare.co.uk or visit reesinkturfcare.co.uk.