Product test: Toro LT-F3000 triple flail mower

Having tried a pre-production Toro LT-F3000 triple flail mower back in early 2016, the chance to have a go on the current Stage V model that was updated in 2021 was too good to miss for independent machinery tester James de Havilland.

First impressions

At first glance, little seems to have changed. The flail cutting heads now carry F-30 decals but appear to be the same as FCF30 units fitted to ‘first generation’ LT-F3000 and current models have CrossTrax on the engine hood. The throttle lever of the previous model makes way for a rocker switch with three settings: idle, high idle for transport and full throttle for work. Simple.

Another feature that was not on the first model I tried was the familiar Toro InfoCenter system, this simple display showing operating hours and other details such as when the next service is due as well as providing easy access to various parameters such the engine DPF filter regen process and accessing operating functions like lift in reverse.

Subtle changes, but the core ability of the original models remains intact. The LT-F3000 is a versatile mowing machine.

Versatility meets quality of cut where the F-30 flail heads of the LT-F3000 score is in their ability to offer a great halfway point between the cutting finish of a commercial cylinder mower with the versatility and rough mowing abilities of a rotary.

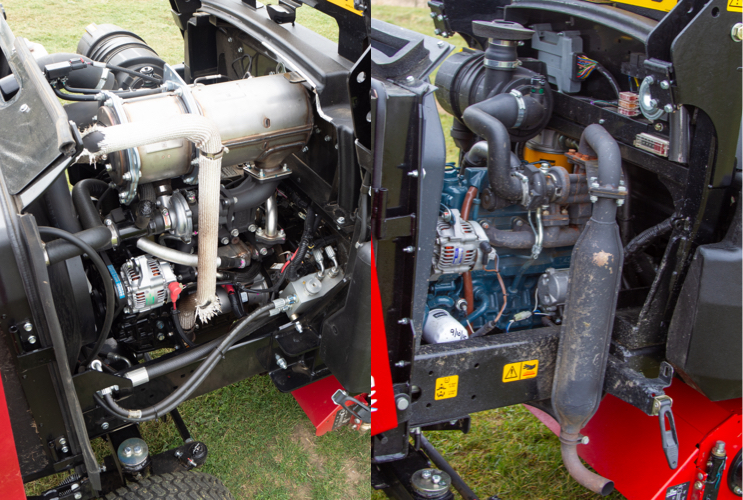

Key changes made to the latest Stage V models relate to the power unit. ‘First generation’ mowers are powered by a four-cylinder 44.2hp Kubota turbo diesel, a 43.4hp Yanmar turbo triple with DPF diesel particulate filter driving the current models.

The other key change is fitting CrossTrax hydrostatic drive as standard. This unique Toro all-wheel drive system links drive between the front wheels and their opposite number at the rear, automatically modulating power between the wheel drive motors. This is claimed to reduce wheelspin and turf marking in slippery conditions plus deliver good traction over steeply undulating ground without creating wheel scuff in a tight turn.

These ‘traction without scuff’ claims proved difficult to put to the test during my drive but when turning the mower at speed at full lock the LT-F3000 proved easy to spin round without cutting up the turf in the process. The ability of CrossTrax to keep going over slippery terrain and inclines, plus working on sidling ground, should be good but CrossTrax will put turf care ahead of ultimate traction. Where the traction is a priority, Toro offer conventional differential lock and 4WD in reverse as an option.

Toro’s LT-F3000 is put through its paces.

Easy mowing

With separate forward and reverse travel pedals, using the mower is as easy as you would expect. The triplex flail units are raised and lowered via individual toggle switches, with drive engaged to each via separate yellow paddles. All controls are laid out in familiar Toro fashion.

In work, the engine is throttled up to full speed via the electronic throttle, dropping the engine speed to a fast idle delivering the full transport speed of around 15mph. That is a fuel saving bonus.

The travel pedals are well-weighted, enabling the working speed to be easily matched to prevailing conditions. The key to getting the best from the flails is to allow them to spin at full speed. Longer patches of scrub could be tackled at speed, short dense patches of grass responding well to a slower mow.

The need to slow down in dense grass was in part due to the mower being set at its lowest cut height of just 20mm or around 0.75 inch. This ‘scalping’ of infrequently mown ground demanded full power to cope with what turned out to be a thick matt of tangled grass.

What about the finish?

The mower did a great job. Cut material was well lacerated, which should speed its decomposition, and it was also distributed evenly across the mown width. Think cylinder clippings but fluffed up. Clipping spread was extremely well controlled. Working adjacent to a track, the spread of material from the mown to hard surface was minimal, with no need for a post-cut clean up. You could confidently work this flail mower alongside parked cars or in a public space.

The flails will allow some long stems to pass through uncut and flattened long material was left in the odd spot. As with all mowing systems, there will be compromises but overall, the flails did a great job. I doubt a rotary mower would have done better and a cylinder mower would just not be the right tool for the work tackled on the day.

That said, it would be interesting to compare to the finish between the F-30 flails and Toro four-blade Mk3 commercial cylinders as fitted to the LT3340 cylinder mower (6- and 8-blade units also available). On regularly maintained turf the chances are the cylinder mower would put up a stiff fight but over the ground mown during this test it would have been a hands down win for the LT-F3000 over the rough patches.

Toro does offer a cylinder kit for the LT-F3000, incidentally, so you can do a swap if you want but most will be happy to stick with just the flails. Not only do they do a great job, but their reduced maintenance demands are also a further point to consider. There are 16 Toro Tempest flails per F-30 head. Allow a short morning with a couple of spanners and all the flails can be renewed. If you are the one signing the maintenance cheque, it is easy to see why a flail mower will have its attractions.

A point to note, is that opting for flails has a downside. The LF-T3000 has a more powerful engine than a triple cylinder commercial mower such as the Toro LT3340. Cutting the same 2120mm in a pass, an LT3340 is likely to use less fuel, particularly over regularly mown grass. Mixed mowing in less-than-ideal conditions? A harder call.

My conclusion following the drive of the original LT-F3000 back in 2016 was that the only way to judge the system is to try it out. My drive this time around saw me mow over a few hidden lumps of concrete hidden in the turf, tackling patches of long, short and matted grass, plus some scrub and heavily weed infested ground. The mower tackled everything without fuss, delivering a decent looking ‘maintained’ finish in a single pass.

Would the LT-F3000 do a better job than something like a Toro Groundsmaster rotary mower? Would a commercial cylinder mower with four-blade reels have produced a better finish? As I said last time around, I cannot answer that but can say if you have not tried a flail mower you could be missing out on a truly versatile piece of kit. The LT-F3000 is popular for a reason.

Tackling areas of infrequently mown ground is increasingly common, with conservation mowing having to adhere to regimes aimed at increasing biodiversity. Working over weed infested turf, the LT-F3000 did a good job, leaving the well-mulched cut material evenly across the mown width. A rotary mower could perhaps deal better with the long stalks of teasel, but the flails picked up and cut most matted grass well and left a good overall finish.

Heavy and dense grass takes a good deal of power to cut. The mowing conditions here could have possibly defeated the cylinders of a commercial cylinder mower, a rotary perhaps doing a decent job. As shown in the picture of the cut material exiting the flail head, the clippings were evenly distributed.

Service access is enhanced by the fold up operator platform and one-piece engine hood. There are grease points on the flail heads and fold system, but daily checks and routine care do not appear onerous.

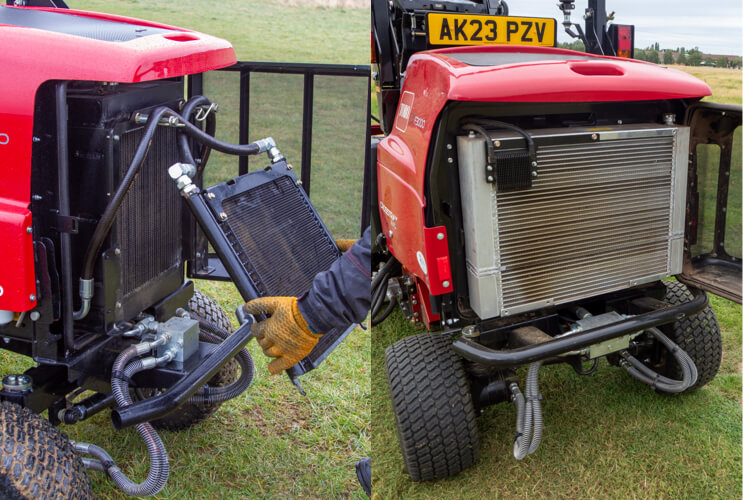

Kubota engine ‘first gen’ models feature separate engine and oil cooling radiators, the current Stage V Yanmar engine mowers having a two-section single alloy radiator to do the same job. In work, the rear screen soon gets covered in clippings, but when opened debris fell away. Overheating, despite Stage V exhausts running at high temperatures, should not be a problem.

Toro InfoCenter display is simple and easy to work through. When selected, the ‘limited lift reverse’ system will slightly raise the cutting units in reverse. This works well but there may be conditions when it is best switched off; this can include when mowing up to and under an obstacle, such as a park bench.

All-wheel drive ensures good traction, the Toro CrossTrax system ensuring this is not at the expense of turf care, with scuff in tight turns and a loss of grip to a single wheel in slippery going being reduced. A more ‘conventional’ 4WD drive systems is available as option.

The supplied spanner is used to adjust the cut height by altering the rear roller’s depth setting. The decal indicates the cut height in inches, ringed sections on the adjustment column showing the selected height. Most set a height and leave it, with the demo mower set to its lowest cut height of 20mm or 0.75 inch.

Stage V models have a revised armrest with electronic throttle replacing the lever of the ‘first generation’ models (left). Note the ignition key is easier to get at in its position next to the InfoCenter.

Fitted with 16 Toro Tempest flails, the F30 flail heads are much the same as the FCF30 units fitted to the earliest models although the drive motors and flail rotor end cap bearings are of a different design. As an option, the Tempest flails can be swapped to Y types to suit mowing fine turf.

Routine care and cleaning should be straightforward with the flail heads being easier to hose down than the cylinders of a cylinder mower.

Optional road light kit uses LED lamps front and rear plus for the amber beacon. The indicator lights are exceptionally bright and show up well when used as flashing hazard lights.

Developing a 44.2hp / 33kW, the four-cylinder Kubota engine (right) is slightly more powerful than 43.4hp Yanmar triple now fitted to the LT-F3000, but the latter meets tough Stage V emission standards and benefits from an electronic throttle system. In work, the LT-F3000 is pleasingly quiet.